Welcome to our Website

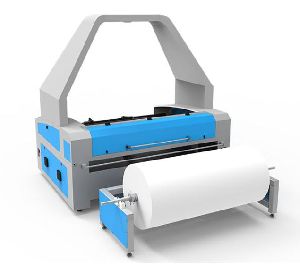

SIL is leading Indian manufacturer of Lasers, Laser systems, Optics, Electro-Optics & Opto-Mechanical Equipment for various industrial & research applications since 1990 based in Pune, Maharashtra, India. Our Managing Director and Visionary Dr. Suresh.T.Shah, a patriotic Indian Laser expert who has Designed, Developed and Produced Various Lasers Systems for Industrial and Research Applications Since 1975, he has dedicated his entire life for MAKE IN INDIA program.We design and manufacture laser machines for various applications such as Cutting, Welding, Cladding, Hardening, Marking, Engraving, Cleaning, with A strong R&D team of 35+ Research Scholars and we thrive to produce high quality systems with most of the technology manufactured in-house. Read more...

Product Range

Why Us ?

We love our clients

We take provide in delivering Intelligent Designs and Engaging Experiences forrnclients all over the World. These are some valuable customers.

Whats makes us different?

SIL is dedicated towards building strong relationships with all stakeholders, customers, distributors, vendors and employees. To our customers we offer a near endless stream of support. It is our goal to keep our customers up and running. We have a huge network of talented suppliers and distributors.